Strong Demand: JK Paper recorded its highest ever quarterly Consolidated Turnover in Q2

A new capacity in Tissue and specialty paper mfg.; Machine Design, Installation, and commissioning by Saloni Paper Machines

JK Paper reports a 134 percent jump in Q3 profit after tax, maintain its leadership position in Cut –size office paper

"Paper Industry will no longer be in the traditional 3-5 years of cycles": FPTA

TNPL will focus on increasing its market share in Virgin Fiber grades; Intends to strengthen the dealer network

A new double wire paper mill of Kraft paper productions started in Madhya Pradesh

Several agile interventions helped ITC-PSPD fortify its clear leadership of the Value Added Paperboards (VAP) segment

Century Pulp & Paper is working towards innovative plastic replacement products

CPPRI: Paper Industry contributes Rs. 8000 Crores to the National exchequer with a turnover of Rs.70000 Crores

Satia Industries: better product mix and higher sales realization drive increased revenue in Q2FY23

Vishal Paper Mills to Produce Multi Layered Card Board Material for Packaging

“Many suppliers have adjusted pricing to account for the ITC impact, which has resulted in an overall increase in paper prices,” says Mr. Hardik Shah, CEO -Sundaram Multi Pap

Printers demand single slab of 12% GST on all converted/printed products: AIFMP

Paper Market scenario of WPP, Coated, and Packaging Boards, and MIP impact: Insights by Mr. Bhavesh Gala

“Many suppliers have adjusted pricing to account for the ITC impact, which has resulted in an overall increase in paper prices,” says Mr. Hardik Shah, CEO -Sundaram Multi Pap

“FCBM urges brands to recognize the value addition by corrugators and ensure equitable pricing,” says Mr. T. M. Raghavan of FCBM

Seshasayee Paper to raise capacity from 2.55 to 4 lakh tonnes, backed by a Rs 750–800 crore investment plan over the next two years

"It is estimated that $10B to $20B worth of single-use plastic packaging will convert to molded fiber": ZUME

EBMA: With books exempt from GST, imported finished books enter India tax-free; notebook prices may climb 15–20% with GST hike

Muzaffarnagar gets a new capacity of Tissue Paper and MG Poster paper

BioCNG from paper mill effluent: India’s & Asia’s First Paper mill, Sainsons Paper to Produce & Sell CBG/BioCNG From Waste Water

From Base Paper to Barrier Coatings: Pudumjee's ED Outlines Roadmap for Greener Packaging

Kraft Paper Market: Current Scenario, Policy Impact, and Outlook for 2026

Fiber Recovery And Water Reuse in Paper Mills Through Closed Water Loop- A need of hour

The Pulp and Paper Times, November 2016 Issue

The Pulp and Paper Times: Volume 1 issue 6

The Pulp and Paper Times: Volume 2 issue 1

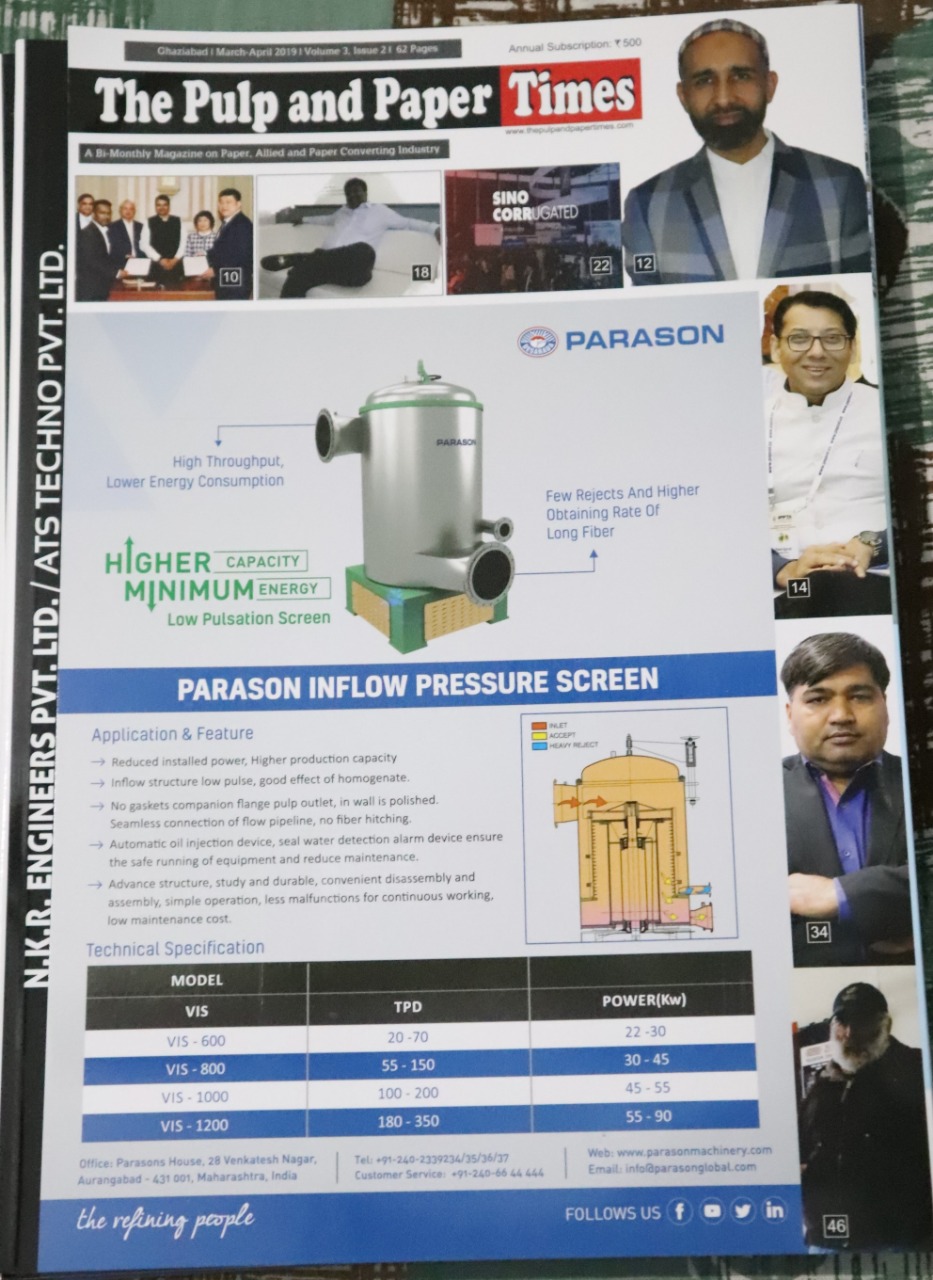

The Pulp and Paper Times : Volume 3 Issue 2

The Pulp and Paper Times: Volume 4, Issue 5

The Pulp and Paper Times Magazine : Volume 5, Issue 2

The Pulp and Paper Times Magazine : Volume 6, Issue 1

For the first time in India, scientists from IIT-Guwahati have developed biodegradable plastic with the help of homegrown technology.

In a country where rising pollution levels remain a serious area of concern, the innovation comes as a major shot in the arm for solid waste management.

The biodegradable plastic has been developed by IIT-G's Centre of Excellence-Sustainable Polymers (CoE-SusPol), which is funded by the department of chemicals and petrochemicals under Union ministry of chemicals and fertilizers. The centre has already developed kitchen cutlery, household furniture and decorative items including flower pots and toys using this non-biodegradable plastic variant.

Vimal Katiyar, CoE-SusPol coordinator and principal investigator of the project, says, “Ours is the only centre in India which is carrying out research on biodegradable plastic. Though the US has been a major producer of biodegradable plastic, the production costs there are very high. But our team has managed to achieve this with lower costs by using homegrown technology. This is a cutting-edge innovation and a remarkable achievement.â€

He added that the biodegradable plastic, which has passed the hot-beverage test, is unique because it has no hazardous chemicals.

“The non-biodegradable plastic products, which are commonly used in households, cannot be recycled for 400 years. Products like plastic carry bags, if disposed of unscientifically, are hard to decompose and are a massive threat to soil cultivation,†Katiyar said.

As environmentalists battle to solve the problem of plastic pollution, the biggest challenge before scientists today is to come up with biodegradable plastic products. Katiyar pointed out that the IIT-G project is a major step in the direction, as their plastic variant is non-polluting and will help increase soil fertility. “The biodegradable plastic that we have developed can perfectly replace the non-biodegradable variant. Our biodegradable plastic does not come from petroleum, but bio-based, which is safe and environment-friendly. When products made out of the biodegradable plastic variant will be thrown in the garbage dump, they will degrade automatically and get absorbed in the soil. This plastic will help increase soil fertility,†he said.

The project has now found support in a Gujarat-based private company which has offered help to IIT-G to begin commercial production. Till now, the IIT-G centre has been producing 7-8 kg of biodegradable plastic at one go. But Katiyar said that a pilot project, with a 100 tonnes per year capacity design, will go on till September this year. Successful completion of the pilot project will pave the way for commercial production, he added. Source: TOI