Strong Demand: JK Paper recorded its highest ever quarterly Consolidated Turnover in Q2

A new capacity in Tissue and specialty paper mfg.; Machine Design, Installation, and commissioning by Saloni Paper Machines

JK Paper reports a 134 percent jump in Q3 profit after tax, maintain its leadership position in Cut –size office paper

"Paper Industry will no longer be in the traditional 3-5 years of cycles": FPTA

TNPL will focus on increasing its market share in Virgin Fiber grades; Intends to strengthen the dealer network

A new double wire paper mill of Kraft paper productions started in Madhya Pradesh

Several agile interventions helped ITC-PSPD fortify its clear leadership of the Value Added Paperboards (VAP) segment

Century Pulp & Paper is working towards innovative plastic replacement products

CPPRI: Paper Industry contributes Rs. 8000 Crores to the National exchequer with a turnover of Rs.70000 Crores

Satia Industries: better product mix and higher sales realization drive increased revenue in Q2FY23

Vishal Paper Mills to Produce Multi Layered Card Board Material for Packaging

“Many suppliers have adjusted pricing to account for the ITC impact, which has resulted in an overall increase in paper prices,” says Mr. Hardik Shah, CEO -Sundaram Multi Pap

Printers demand single slab of 12% GST on all converted/printed products: AIFMP

Paper Market scenario of WPP, Coated, and Packaging Boards, and MIP impact: Insights by Mr. Bhavesh Gala

“Many suppliers have adjusted pricing to account for the ITC impact, which has resulted in an overall increase in paper prices,” says Mr. Hardik Shah, CEO -Sundaram Multi Pap

“FCBM urges brands to recognize the value addition by corrugators and ensure equitable pricing,” says Mr. T. M. Raghavan of FCBM

Seshasayee Paper to raise capacity from 2.55 to 4 lakh tonnes, backed by a Rs 750–800 crore investment plan over the next two years

"It is estimated that $10B to $20B worth of single-use plastic packaging will convert to molded fiber": ZUME

EBMA: With books exempt from GST, imported finished books enter India tax-free; notebook prices may climb 15–20% with GST hike

Muzaffarnagar gets a new capacity of Tissue Paper and MG Poster paper

BioCNG from paper mill effluent: India’s & Asia’s First Paper mill, Sainsons Paper to Produce & Sell CBG/BioCNG From Waste Water

From Base Paper to Barrier Coatings: Pudumjee's ED Outlines Roadmap for Greener Packaging

Kraft Paper Market: Current Scenario, Policy Impact, and Outlook for 2026

Fiber Recovery And Water Reuse in Paper Mills Through Closed Water Loop- A need of hour

The Pulp and Paper Times, November 2016 Issue

The Pulp and Paper Times: Volume 1 issue 6

The Pulp and Paper Times: Volume 2 issue 1

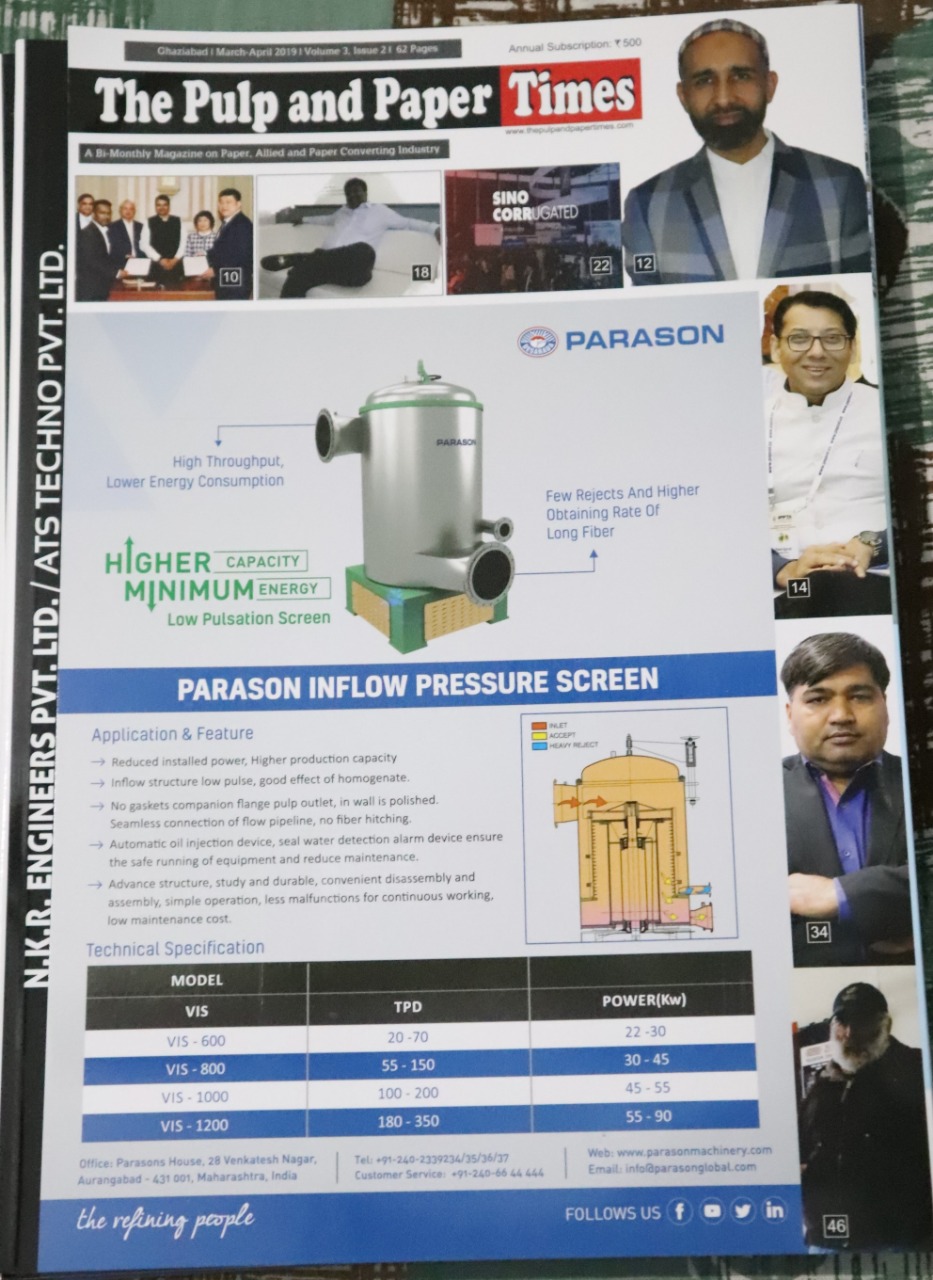

The Pulp and Paper Times : Volume 3 Issue 2

The Pulp and Paper Times: Volume 4, Issue 5

The Pulp and Paper Times Magazine : Volume 5, Issue 2

The Pulp and Paper Times Magazine : Volume 6, Issue 1

Malerkotla | 28 Feb 2019 | The Pulp and Paper Times:

“Cardboard is a multipurpose product that allows products of all sorts to be packaged and shipped economically and ecologically. Cardboard is lighter than wood (and in most cases plastic) and can be made from both wood pulp chips and recycled material. In turn, it is recyclable and biodegradable. The mechanical properties of cardboard come from its corrugated or crimped centre of from its thickness. It can be made in a wide variety of thicknesses to meet various specifications. Since it is robust and shock-resistant, keeping out light and dust, it can be used as bulk packaging for storage or transport, but also final packaging since it can be treated, coated and printed to make commercially attractive boxes,†explained by Mr. Krishan Mohan Gupta, Managing Director of Vishal Paper Mills Pvt. Ltd.

After being already engaged in duplex Board manufacturing, Vishal Paper has decided to deploy a separate multilayer Card Board line in the existing paper mill. “Yes, we have undergone to produce 100 TPD cardboard for different kind of boxes and other packaging solution. We are expected to start the commercial production by April or May 2019. The end use of cardboard is for boxes like a mobile box, sweet box and other boxes in heavy GSM range,†Mr. Gupta said.

Cardboard containers are the cheapest form of packaging which helps in reducing the final product price on account of bundling with packaging which in turn is expected to increase its demand for packaging purposes in medical instruments, food & beverages and household electronic appliances.

The product is biodegradable and recyclable and poses the least impact on the environment. Their environment-friendly nature is expected to increase their preference over their alternatives which include plastics and polymers.

“The construction is almost completed and Plant and Machinery erection work is scheduled to start. We are importing the plant and machinery from China to make 600 GSM to 2500 GSM cardboard. The deckle of the machine will 1.8 meters and speed is designed at 80 m/min,†Mr. Gupta informed.

Over the decades, cardboard box manufacturing has been labour intensive. There has been significant progress in automating the manufacturing process. However, labor is still a vital for designing, machine operations, sales and management. Investment in technology is expected to increase, thus driving it towards being a capital intensive industry.

The global market is segmented on the basis of container dimension and usage which further include paperboard and corrugated cardboard. The small size boxes generally used for food and beverages packaging are termed as paper boards. Within the food and beverage industry, paper boards are widely used in confectionaries, cereals and ready to consume fruit drink packaging.